Industrial Safety: Slips, Trips, and Fall Prevention

Slips, trips and falls are some of the most common workplace injuries reported at industrial worksites. These types of accidents can have a range of serious consequences, from minor scrapes and bruises to more severe sprains, breaks or worse.

To reduce the risk of these kinds of injuries in your workplace, it’s important to take proactive steps to identify potential hazards and address them quickly. In this blog, we’ll explore common causes of slips and falls, and discuss some practical tips to help prevent them from happening.

Understanding Slip, Trip, and Fall Hazards

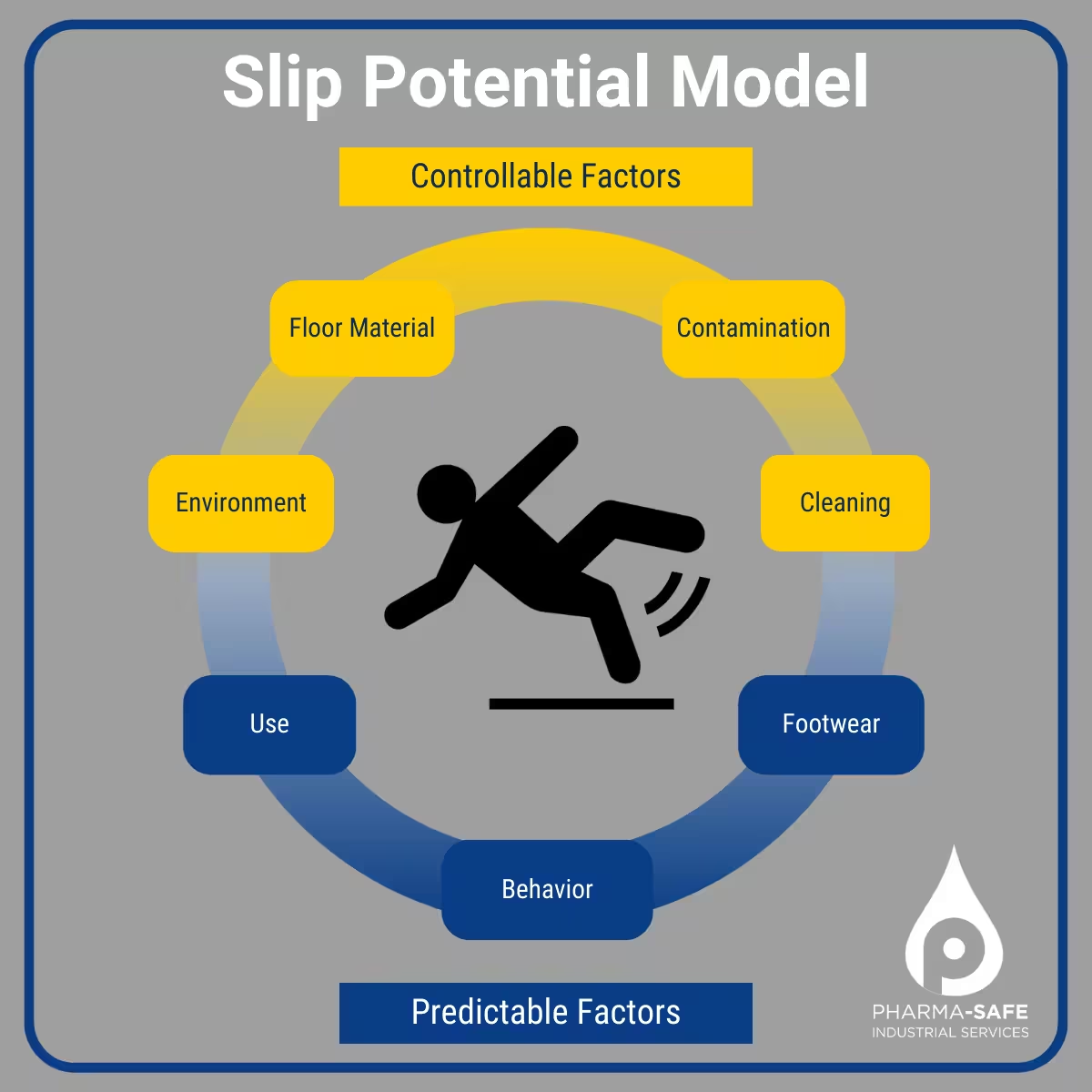

The most comprehensive model for predicting and preventing slips, trips, and falls in the workplace is represented with the slip potential model.

The slip potential model outlines seven factors in two categories: controllable and predictable factors.

Controllable factors:

- Environment: Understanding the context in which the space is used is essential to determining what precautions should be taken. Is the flooring in an inside or outside environment? What kinds of activity happen in and outside of the workspace? What is the level of foot traffic? Do workers climb or work on elevated stations in this area?

- Floor Material: Floor material should suit the environment’s needs and be adjusted as necessary. How worn down is the flooring, and how does that effect the risk of slips, trips, and falls? Are there additional measures that can be taken to reduce moisture, such as entry mats?

- Contamination: Even if floor material is well suited to the environment, it inevitably becomes dirty, presenting new risks. What kind of contamination is it? How can you prevent the contamination from continuing or happening in the future?

- Cleaning: Directly related to floor material and contamination, cleaning itself can solve contamination issues, but can also create new risks. What kind of cleaning is required to remove the contamination safely? What kinds of chemicals are safe for this floor material? Does cleaning leave wet, oily, soapy, or toxic remnants? How will you indicate that an area should be avoided while being cleaned?

Predictable factors involve managing risks for individual workers. Use, human factors and behavior, and footwear can all help address the risk of human error.

Common Causes of Slips, Trips, and Falls in Industrial Workplaces

The most common causes of slips and falls in the workplace include wet or oily surfaces, poor lighting conditions, an accumulation of clutter or debris on walkways, obstructed views, or pathway obstacles, such as exposed wires or misplaced tools.

Another frequent, more severe source of slips and falls is using ladders and scaffolding at various heights. One wrong move on an elevated platform can be catastrophic, so employees should exercise extra caution when performing these duties.

These types of incidents can result in workers receiving serious injuries such as fractures, head injuries, or spinal damage, as well as long-term health issues such as chronic pain or loss of mobility.

Preventing Harm with Proactive Safety Practices

It is important to regularly assess the worksite for any potential threats that could lead to an accident. This should include inspecting flooring, ladders, and railings for any damaged areas, loose boards, or a lack of non-slip surfaces. In addition, any falling objects or debris should be cleared away, and all pathways must be visible and free from obstruction.

Investing in the proper personal protective equipment (PPE) can significantly reduce the risks of slips and falls and should be enforced according to industry regulations.

For example, steel-toed boots provide excellent protection against heavy materials falling on your feet and provide more grip on slick surfaces. Harnesses and safety nets offer extra protection on elevated platform setups.

Additionally, adequate lighting is essential so workers can see potential tripping hazards and mitigate them promptly.

Creating a Safety Culture

Developing and implementing a comprehensive safety program is the best way to prevent slips, trips, and falls at an industrial worksite. You can significantly reduce the risk of injuries in your workplace by taking proactive steps and implementing a comprehensive safety plan with clear policies around safe working practices.

This safety plan should include the following:

- Processes and policies for creating and maintaining a safe working environment

- Applications of appropriate cautionary signage to warn of potential hazards

- Proper training programs on fall prevention and the use of ladders or scaffolding in your facility

- Appropriate PPE to protect workers from slips, trips, and falls

- Routine safety and equipment inspections

- Accident/incident case management and reporting protocols

- Employee engagement standards

Once a safety program has been established, the protocols must be adhered to by all staff members and communicated in your recurring toolbox safety talks. By taking these steps, companies in the industrial and energy sectors can dramatically reduce the risk of slips and falls in their workplaces, which, in turn—will keep employees safe, healthy, and productive.

Your Strategic Safety Partner

Pharma-Safe Industrial Services is the perfect partner for any industrial organization looking to improve its HSE compliance and safety management systems. With varying years of experience, our highly-trained consultants have the knowledge and expertise to develop tailored solutions that meet your company’s specific needs.

Contact us to get started on improving your safety programs today!

1 Comment