The safety culture in the oil and gas industry has been a long, hard-fought journey of growth and learning—a true cautionary tale defined by the motto, “We can always do better.”

Over time, the industry has embraced stricter regulations, enhanced training, and cutting-edge technology to safeguard workers better. Yet, accidents serve as constant reminders of the industry’s most critical priority: safety.

In this article, we’ll explore the history of safety in the oil and gas sector, from early oversight to modern-day advancements, and look ahead at emerging trends in safety training and technology that are shaping a safer future.

The Early Days: Pre-1900

In the 1800s, safety was an unknown concept in oil and gas extraction. Following the Industrial Revolution, oil demand surged, leading to the rapid growth of the industry. However, this expansion brought new hazards that workers faced without protection or guidelines.

From hazardous recovery techniques to improper storage and handling, deaths and injuries were an accepted commodity that was rarely recorded. According to the American Oil and Gas Historical Society, most oil wells were dug or chiseled by hand. Experience was judged by the number of fingers still attached in some areas. Employees were exposed to life-threatening risks.

Equipment shielding, like steel plates around machinery, was prioritized over worker safety, exposing employees to life-threatening risks.

The 19th century saw the first murmurs of a safety mindset, though primarily directed at protecting equipment to reduce operational losses rather than safeguarding lives. Despite the constant danger, the groundwork was laid for future labor rights and safety considerations.

The Rise of Labor Movements: 1900s–1960s

The early 20th century introduced labor movement waves focused on improving working conditions across various industries.

New technologies and processes emerged in the oil and gas industry. Efficient oil recovery and rotary rigs were introduced, and new refining and storage techniques were implemented while workers continued to bear the brunt of a lack of safety.

Despite these technological improvements, oil and gas extraction remained highly dangerous, with corporations resisting change due to the lack of legal repercussions for unsafe practices.

Labor strikes and grassroots campaigns in the 1930s and 1940s highlighted the need for safer conditions, though oil-specific safety regulations stayed scarce.

The basis for worker’s rights began in the early 20th century, with certain protections only applied to limited industries and companies for limited amounts of time. Some states created safety and health standards, but they were few and far between.

However, businesses lobbied strongly against labor protection efforts.

The oil and gas extraction industry has always been a dangerous occupation; in 1913 alone, the Bureau of Labor Statistics recorded more than 23,000 workplace deaths, the majority being oil and gas-related.

Despite this, improvements in other energy industries were hopeful signs for the future. The seeds of safety planted decades prior started to peek from beneath the soil with Hollywood bringing awareness to safety for oil workers with mainstream movies such as Thunder Bay (1953).

Meanwhile, offshore oil drilling technology began to grow.

The Oil Is Offshore: 1970-1990s

With onshore production stalling, demand accelerating, and various geopolitical turmoils, it made economic sense to justify the expense of producing oil offshore. This also brought increased safety challenges for both workers and equipment.

Under pressure to meet rising demand, companies operated on tight schedules with drilling vessels contracted by the day. This increased the risks due to speed-focused operations. While regulatory mandates existed as early as the ‘60s to ensure worker safety, these orders didn’t necessitate testing standards, design criteria, or technical requirements.

Several high-profile disasters, such as Shell’s Baker Platform fire, the Alexander L. Kielland sinking, the sinking of the Glomar Java, the Ocean Ranger, and, worst of all, the Piper Alpha Disaster, forced the industry to reevaluate the need for worker safety.

The 2000s and Major Reforms

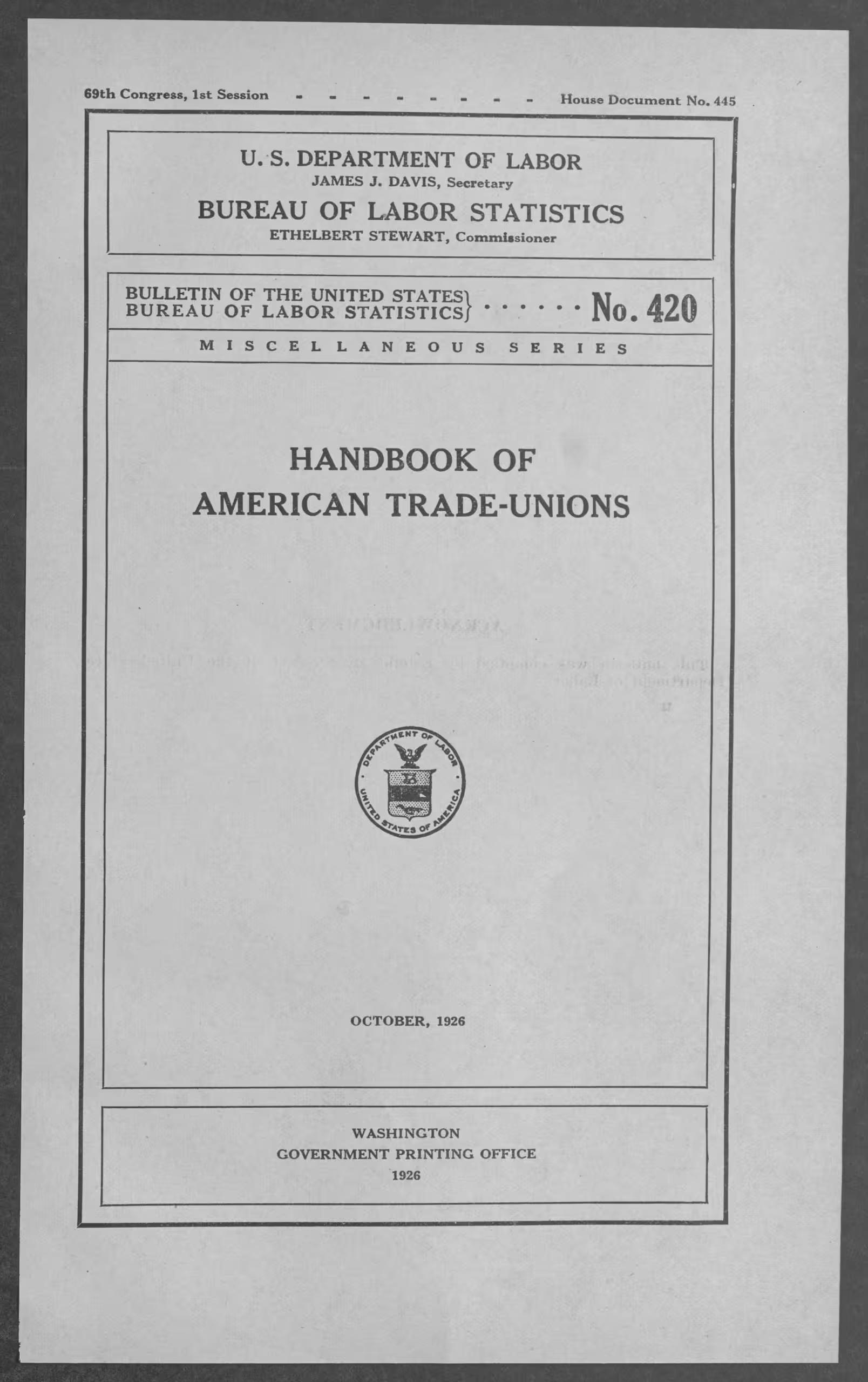

High-profile incidents in the 21st century showed the need for stronger regulatory oversight. Events like the 2005 Texas City BP refinery explosions and the BP Deepwater Horizon disaster clearly demonstrated that the motto “we can do better” still applies to the oil and gas industry.

In response, the U.S. Minerals Management Service (MMS) responsible for offshore energy regulation was dissolved and renamed the Bureau of Ocean Energy Management, Regulation and Enforcement (BOEMRE).

Shortly after, the Department of the Interior (DOI) called for additional restructuring, which split the new bureau into three separate agencies to enforce worker safety, environmental responsibility and protection, and natural resource conservation.

One of the newly formed agencies, The Bureau of Safety and Environmental Enforcement (BSEE), oversees safety, response, and removal activities for offshore oil and gas. It also investigates, suspends, and levies penalties related to violations concerning regulations of offshore exploration and production to reduce offshore risk and improve emergency response.

Federal standards aren’t always enough, though. Infamously, OSHA manages federal standards for Permissible Exposure limits (PELs), which are “regulations that establish the acceptable amount or concentration of a substance in the air in the workplace.”

Despite being forty years out of date, OSHA’s efforts to provide more scientifically accurate PELs for the hundreds of chemicals it does have permission to monitor and adding thousands of additional restrictions on chemical exposures have been impeded by rigorous litigation (AFL-CIO v. OSHA) and a lengthy rule-making process.

This limitation is vital when considering worker safety and emphasizes the importance of going above and beyond regulations for workers.

The National Institute for Occupational Safety and Health (NIOSH) continues to research occupational safety in the oil and gas industry.

A Timeless Motto: “We Can Still Do Better”

We live in an exciting time for oil and gas, where companies are constantly pushing the limits of engineering and design to maximize production through deeper wells and taller offshore rigs.

While the need for a stronger safety culture has been established, it is obvious that more can and still needs to be done to improve overall safety for the oil and gas industry. Companies now understand that in-depth reporting and auditing, a comprehensive safety plan, and interactive hands-on training programs are essential to business growth while instilling a safety culture.

However, there are still several factors that often impede industry-wide safety progress, including:

- Fragmentation among offshore contractors: Smaller contractors may lack the resources to adopt comprehensive safety protocols, resulting in inconsistent safety practices.

- Inconsistent levels of commitment to safety by management staff

- A lack of regulatory compliance oversight

- Conflicting priorities between safety and productivity: Operational pressures can lead to shortcuts, where safety is deprioritized in favor of productivity.

- The “Great Crew Change”: With a large portion of the industry’s skilled workforce nearing retirement, younger, less experienced workers are stepping in. This generational shift creates a pressing need for advanced training to bridge knowledge gaps.

In turn, many companies have turned to independent safety consultants and technicians to fill knowledge and experience gaps and to assist with developing expertise within their organizations. Third-party safety consultants and technicians offer safety audits, training, and quality assurance to help ensure regulatory compliance. This helps companies save time, money, resources, and—most importantly—lives.

The Role of Technology in Modern Safety Training

Using technology for safety auditing and training will continue to help reduce accidents and harmful implications. Blended learning programs that utilize technology for safety, competency, and knowledge-management training have helped to enhance and expedite overall employee training.

Studies have shown that these types of training (a mix of virtual and hands-on experiences) have a stronger and longer-lasting impact on workers, resulting in fewer job safety and health risks. Online resources that use technology for training are becoming the industry norm, incorporating methods such as:

- Video demonstrations — simple tasks such as choosing the correct field gear, safety procedures, and noting hazardous situations can prove more impactful than a slideshow.

- Virtual reality training — allows workers to enter a simulation designed to guide them through an average day on the job and requires them to complete tasks to test their training knowledge and competency.

- The use of tablets and laptops — allows workers access to interactive training programs anytime and anywhere, as long as they have an internet connection.

Looking to the Future of Safety in Oil and Gas

Overall, the evolution of safety in the oil and gas industry has shown that expecting a shift in focus from production and development to safety as an overarching business goal has been slow. For companies involved in the industry, outsourcing safety to qualified contractors offers the most economical and productive way to deliver and refine a safety culture and program that benefits both the company and its workers, while also securing future growth.

Safety consultants such as Pharma-Safe can help your company develop the right programs and methodologies to protect your equipment and workers. We also provide highly trained and certified safety technicians and consultants who work with your staff to ensure your projects meet all regulatory and compliance requirements. Contact us to learn how Pharma-Safe can help your team stay at the forefront of safety compliance and industry regulation.